|

| New spark plugs B8HS for the Yamaha RD 125A |

|

| Battery Yamaha RD125A 1974 - 12V 5.5Ah |

The chrome work of the pipes is still in pretty nick shape but I discovered one of the silencers was missing and I couldn't find them for sale on Internet anymore. The guy I bought the bike form happens to be a boilermaker and offered me to make one. I only had to drill all the little holes (many little holes...), braze a small bar at the end and tap a thread for the mounting screw. perfect fit :)

|

| Fixing a new silencer - Yamaha RD125A 1974 |

|

| Old and new silencer - Yamaha RD125 |

| Melted top of right hand piston |

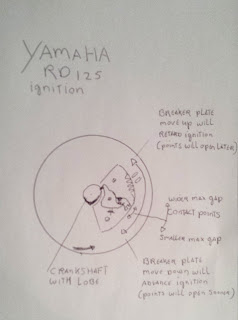

There's more then one way to check the timing of a two stroke Yamaha; The factory mark on the flywheel which has to line up with the static mark on the ignition plate when the contact breaker point starts to open (spark plug will fire). Actually there are two marks opposite each other on the flywheel, one for the left and one for the right cylinder. However there can be a problem with the accuracy of this method because the static mark on the case can be moved by loosening a screw. Maybe your bike was a Monday morning bike or one of the previous owners changed the mark, who knows...

|

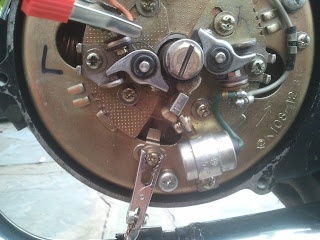

| Ignition timing parts - Yamaha RD125A 1974 |

- Contact breaker points plate

- Contact breaker points (Ignition points)

- Crankshaft which you can turne with a scredriver

- Ignition timing mark on flywheel (there are two)

- Static ignition timing mark on case

- Condensors

- Arrow pointing in direction of running engine

Luckily there's a more accurate method to check the ignition timing. For this method you need a dial indicator gauge a dial gauge adaptor to fit it in the spark plug hole and a feeler gauge.

First of all you have to check the max point gap. This should be somewhere between 0.30 and 0.40 mm. On my bike there's a small mark on the end of the crankshaft so you can see where the top of the lobe is (see pic). Normally the max opening point occurs when the piston is in TDC (top dead centre). This is the moment when the piston changes travel direction at the top of the cylinder.

If the gap is out of specs, loosen the screw a bit, insert a 0.35 mm feeler gauge and move the breaker point till you feel some light resistance when moving the feeler blade. Moving the breaker point up will give a bigger gap, moving it down a smaller gap. thighten the screw and check it one more time, also make sure you put in the feeler blade without an angle which will give a bigger gap.

|

| Measuring the max point gap - Yamaha RD125A 1974 |

For the next step you'll need a special tool which you can buy online, at good bike shop or you can make it yourself. I made one myself because I didn't want to wait a couple of days ;)

I used an old spark plug bottom, a piece of copper pipe, some kind of spacer from an old car and brazed them together. Make sure you dial indicator gauge isn't moving in this tool, tighten it!

|

| Ignition timing tool Yamaha two stroke |

|

| Ignition timing tool Yamaha two stroke |

|

| Ignition timing tool mounted in left cylinder - Yamaha RD |

For the next step it's important to look for the normal rotation direction of your engine. For Yamaha RD bikes this is counter clockwise. There's also an arrow on the flywheel case which points in the right direction.

Make sure you take both spark plugs out before you start the timing procedure! You won't be the first one who starts his lump while checking the timing..

With the dial gauge in the spark plug hole look for the TDC, this is the moment when the dial gauge stops moving up and starts moving down. Now set your dial gauge at zero exactly on this TDC point.

Now turn the crank with a screwdriver 3 mm clockwise (to get rid of play in the crankshaft) and then turn it 1.2 mm counter clockwise. This is the exact point where you want to have your plug sparking (3-1.2=1.8mm).

OK, how will you know it's sparking? The spark plug will generate a spark at the moment the breaker point starts to open. You can check this by connecting a simple 12V light bulb. One wire on a ground and the other wire on the orange or grey lead depending on the cylinder you're checking. (left breaker point has a orange lead an right one a grey lead). As long as the point is closed the bulb will not light but as soon as the breaker point starts to open it will light. Don't forget to put your contact on, switch it off as soon as you've done the check. You don't wanna drain your battery. Make sure you do this while turning the crank counter clockwise. If the light goes on too early (more then 1.8 mm BTDC) there's too much advance, if it's too late it's too retarded. Either way you have to loosen the 2 screws of the breaker plate and move the plate up or down till it's right. For the Yamaha RD's moving the breaker plate clockwise will give you more advance, and moving it counter clockwise will give you more retard timing.

|

| How to move the points and breaker plate Not my best drawing but you get the point ;) |

|

| Connecting the light bulb - ignition timing two stroke RD |

|

| Instead of connecting a light bulb over the breaker point you can also use a spark checker |

There are 3 methods to solve this problem:

1. Buy new points

2. Go for a smaller max ignition gap (let's say 0.2 mm )

3 sand down the brown plastic part that makes contact with the crankshaft lobe

I will go for 1 but for now I'll go with a combination of 2 and 3. Make sure you sand down the plastic part equally (same height overall) and don't sand too much off, keep it above the fine line.

Finally I got the timing spot on. I had to turn the idle screws on the carbs a bit more in to keep the bike running at idle. And it seems to be that the ignition timing points on the flywheel are in the right position, good to know for the next timing workout. Just for fun I also checked the timing with a strobe light. Perfect!

|

| Ignition timing spot on - Yamaha Rd 125 A 1974 |

Starting the RD125A after ignition point adjustments

Update 22-07-2016:

Just fitted the new contact breaker points (part 183-81421-10). As you can see in the pic below the teeth of the contact breaker plate are nice in the center of the screwdriver "lobes". This is always a good starting point when adjusting new points and you've set the max point gap around 0.35 mm.

| New contact breaker points (part number 183-81421-10) |

|

| Setting the new contact breaker points |

|

| Right breaker plate teeth in the center of the screwdriver "lobes |